Innovation in 3D forming

DuraPulp for Life and FRESH have paved the way for new cellulose fibre products

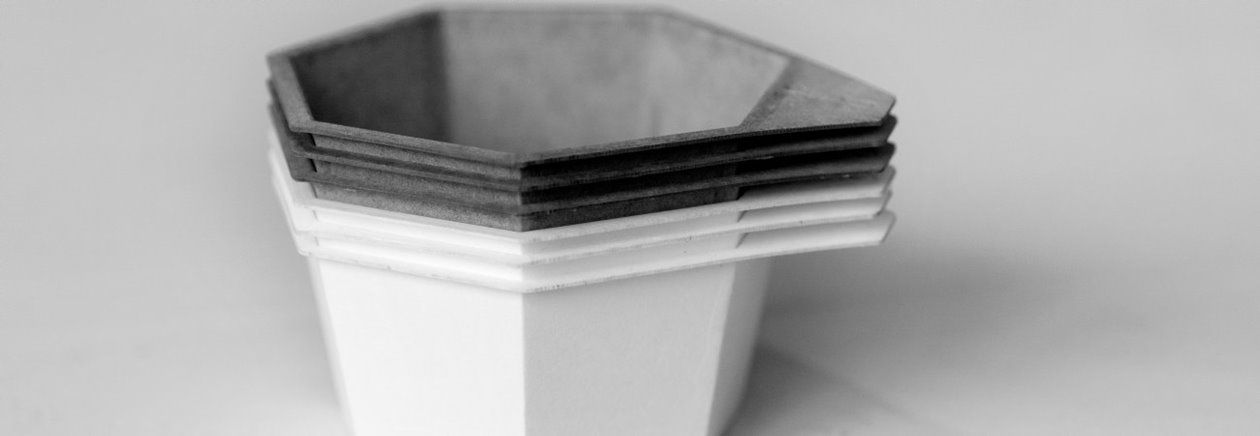

As early as 2000, Södra participated in a research project together with the organisation now known as RISE to produce a composite material called DuraPulp. This development, to see where and how fibres can replace plastic, has since continued. Södra has taken part in two EU-funded projects. The first, DuraPulp for Life, commenced in 2015 and ended in 2019. The main goal of the project was to showcase the production of cellulose fibre products in 3D through dry forming. The aim of the other EU project, FRESH, which will end in 2020, has been to produce biodegradable food packaging from wood pulp by wet moulding. The project was a collaboration between Södra, Huhtamaki and Saladworks.

Due to the lessons learned from many years of development, Södra sees considerable potential for fibres as a replacement for plastics. The fibre can often be used on its own and we no longer see composite materials as the best way forward. We are now focused on forest fibres.